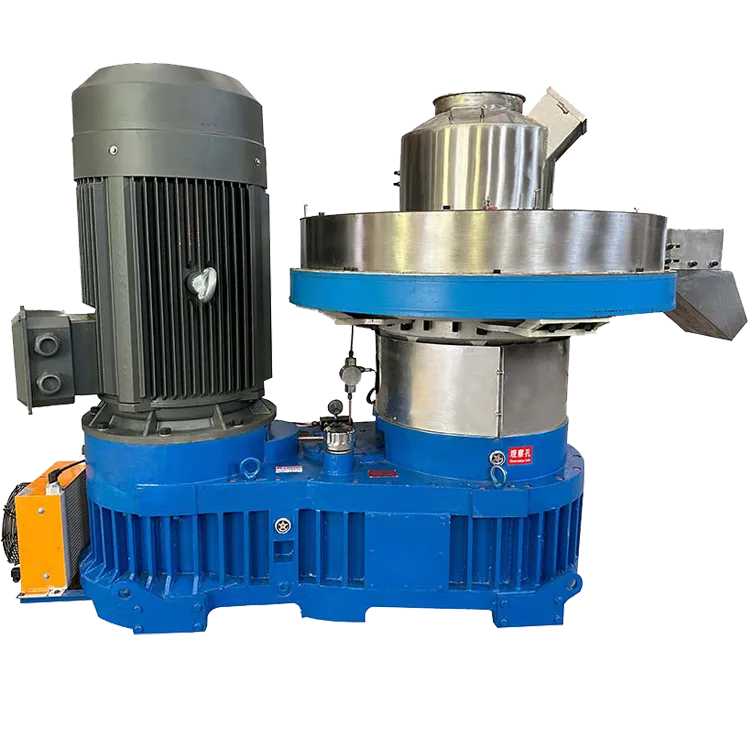

3t/h Pellet Mill for Sale

5.0 based on 25 ratings and reviews

Brand :

TCPEL

Model :

TCZL850

Catagory :

wood pellet mills

Capacity :

3-3.5t/h

Price Range :

$42500-$49800 based on configuration

Payment Term :

T/T/Visa/Mastercard/American Express/Discover cards

Delivery Time :

15days after get deposit payment

3t/h Pellet Mill Introduction

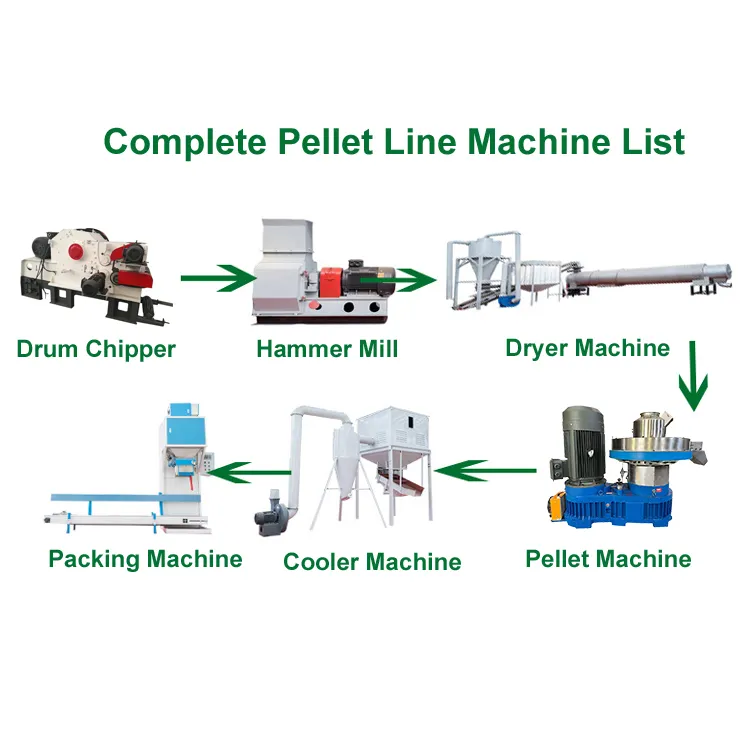

This 3t/h pellet mill is our biggest capacity for single set, the capacity is 3-3.5t/h, with 220kw main motor. This machine is widely used for processing various agricultural and biomass waste into biomass pellets. Because of high power and high capacity, this machine is suitable for large pellet plant more than 10t/h.

Our Pellet Mills Features

Heavy duty structure ensure durable and long-lasting, 24 hours of work time without stop and less maintenance.

Suitable for various materials, including wood, sawdust, rice husk, EFB, palm shell, olive waste, fruit straw beech etc. and more.

Enhanced stainless steel dies have a service life of 1000 to 1500 hours, less power to achieve higher capacity.

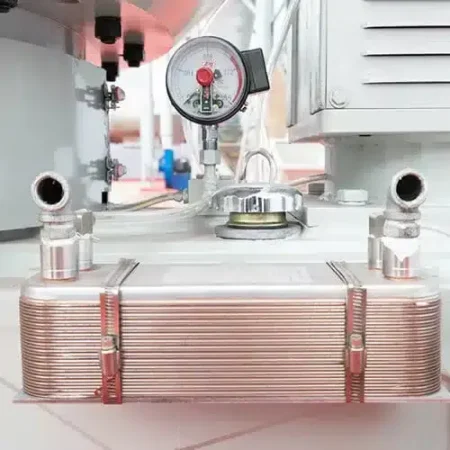

Built-in cooling system and fan blower to help cool down the pelletizing area, ensure continuous high quality output.

The main shaft inside our pellet machine is also wear-resistant, which can ensure produces wood pellets with a smooth, consistent surface.

The vertical laying dies feed directly with a broad range of applications and excellent heat dissipation. It offers improved efficiency with reduced cost.

Pellet Mill Detailed Parameters

| Model | TCZL850 |

| Type | wood pellet mills |

| Output | 3-3.5t/h |

| Main Motor | 220kw |

| Lubrication pump Motor | 0.55kw |

| Pellet collecting Motor | 1.5kw |

| Independent cooling Motor | 1.1kw |

| Material of Ring Die | Stainless steel 4Cr13 |

| Roller Shell | 55# steel |

| Inlet&Feeding Cover | SS304 |

| Pellet Diameter | 6mm,8mm,10mm, 12mm |

| Pellet Length | Can be customized made |

| Pellet Density | 1.0-1.4g/cm3 |

| Machine Weight | 12t |

| Machine Size | 3000*1500*2300mm |

3t/h Pellet Mill Detailed Pictures

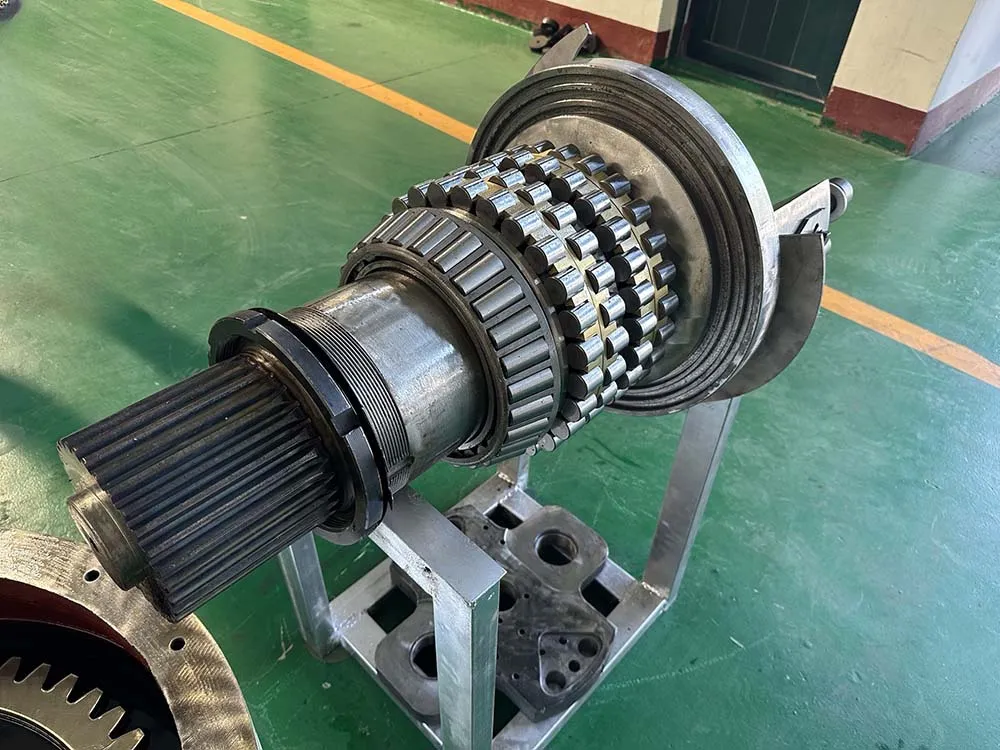

Pellet Mill Machine Spare Parts

Pellet Mills - The Beginner's Guide

Whether you produce pellets for commercial or domestic purposes, you need pellet mills that assure quality and efficiency. We know it is tricky to find reliable wood pellet mills as all manufacturers claim their products to be the best. This comprehensive guide aims to give you adequate knowledge about pellet mill machines, their types, and their functionality. We believe it will assist you in selecting the appropriate mill for your needs.

What Are Pellet Mills?

You must have a fundamental understanding of the machine before investing in it. A lot of people have confusion about pellet mills. Some people compare it to a grinding mill.

Pellet mills, also called pellet presses, turn powdered raw material into a solid mass. Like a grinder, they do not break material into pieces. It does the reverse. Pellet mills merge powdered or crushed material into a uniform mass.

A wide range of pellet mills is available in the market to process different raw materials. For example, a biomass pellet mill is different from an Alfalfa pellet mill.

What is the Use of Pellet Mills?

As we mentioned in the above answer, pellet mills let you produce pellets out of powdered material. Depending on the type of mill you buy, you will use it for making biomass pellets or feed pellets.

Nowadays, pellet mills are available in different sizes and types. If you have to produce pellets on the mass scale or start your pellet production line, go for an industrial pellet mill.

On the other hand, if you want to make wood pellets to keep your homes cozy, a mini pellet mill is sufficient for you.

Decide what you want to do with the pellet machine and make investments accordingly.

How Do Pellet Mills Work?

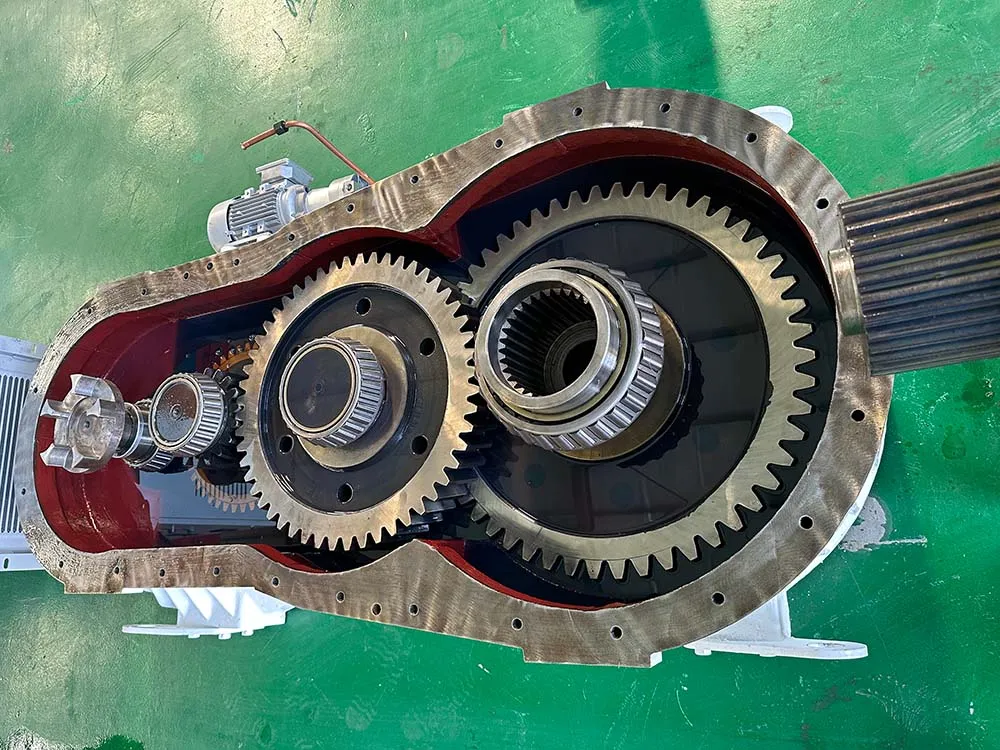

Before you learn how a pellet mill works, get yourself familiar with its numerous components. A pellet mill consists of several parts. However, the main operational parts are the shaft, bearings, gears, and dies.

Almost all pellet mills operate in the same way, with minor exceptions. If we take an example of a wood pellet mill, it has two types:

- Flat die pellet mill

- Ring die pellet mill

Because of the difference in the die types, there is little difference in how these two pellet mills work.

A flat die wood pellet machine features a flat die with various slots. When the raw material reaches the top of the die, it begins to rotate and the roller pushes the material through the slots. The die also has a cutter on the other side that cuts the processed pellets.

In the Ring die pellet machine, the powdered material is always on the inner finishing of a rotating die, attached to rollers. Rollers compress the raw material and pass it through die holes as solid pellets.

Similarly, industrial machines operate little differently than domestic use pellet mills.

How Much Does a Pellet Mill Cost?

Pellet mills are available in a variety of price ranges on the market. The price of a one pellet mill could be $300, while another may cost you $10,000.

You might be surprised to see the difference in the price. Well, several factors influence the cost of the mill. These reasons range from the size of the mill, type of mill, country of origin, and more.

First, determine your requirements before choosing the pellet-making machine. If you want to produce pellet mills for commercial use, choose an industrial pellet mill. For a small number of pellets every day, you can buy home pellet mills.

Finding a reliable manufacturer could be your best step to not overpay for your pellet mill. Look for a company with a long history of manufacturing and connections to transportation/shipping companies. Such manufacturers can deliver machines to your place at the best price.

How Many Types of Pellet Mills Are There?

There are many different types of pellet mills available if you search. Grass pellet mill, hemp pellet mill, industrial pellet mill, Alfalfa pellet mill, and more. You name it, and you will find that pellet mill in the market.

Nevertheless, we can divide pellet mills into three categories based on the following aspects.

1. Engine Type

Though most pellet mills operate on electrical energy, you can also buy a diesel pellet mill. Such mills do not require electricity, instead operate on diesel fuel, thanks to their diesel engine.

2. Amount of Pellets They Produce

You can buy pellet mils based on production capacity as well. Industrial pellet mills are for individuals who operate a pellet production line.

These machines have a ring die and give massive output. On the contrary, flat-die mills are for small production.

3. Usage of Pellet Mills

When it comes to application, not every pellet mill is the same. Some make feed while others fuel.

How to Choose the Best Pellet Mills for Pellet Production?

When purchasing pellet mills, there are a few things to consider. It ranges from the type of material you want to process, how much quantity you want to process, and more. Let us discuss different factors to help you choose ideal pellet mills.

Determine The Type of Material You Want to Process

Not all pellet mills process the same material. So, first and foremost, you must identify what type of material you wish to process. For example, if you want to make biomass pellets, choose the mill that processes wood. For feed pellets, you will have to select the machine that processes relevant material.

Consider the Output You are Looking for

Once you have decided on the raw material you want to process, choose the size of the machine. With a small mill, you can process up to 800kg per hour. On the other hand, commercial mills let you process raw material up to 2,000kg.

Choose a Reputable Manufacturer

The third step you have to take is, choosing a reputable manufacturer. It has a significant impact on the quality of the final output. Make sure the manufacturer has good experience and uses quality material in making their machines.

Ask the manufacturer if they pass CE, ISO, GOST, and other necessary certifications. They should also provide you with after-sales support.

Analyze the Interior and Exterior of Machine

The machine you choose must have a professional exterior. The outer surface must be polished to smooth. Also, ensure that the manufacturer has used high-grade metal in the machine.

Pay attention to the interior of the machine as well. Check the quality of pellet mill dies. Make sure it has smooth finishing on both surfaces. Also, the holes of the die should be uniform.

Take a test run to analyze if the die is rotating accurately. If you notice any weird sound or shaking of the die, report to the manufacturer about it

Check the Power Consumption

Look for pellet mills that have lower power consumption and higher efficiency. Otherwise, you will not get good returns on the investment.

Get to know how much KW of electricity your mill consumes for a particular amount of pellets.

For example, the Tcpel TCZL560 wood pellet mill requires 90KW power to produce 1-105t pellets.

Other things you have to consider are the safety and user-friendliness of the machine.

How to Buy an Affordable Pellet Mills?

Different types of pellet mills are available on the market, as we discussed in the last section. You should be aware that the price of a pellet mill is decided by its kind, size, and other factors.

As a result, you should keep a few factors in mind when looking for a low-cost pellet mill. These include:

Choose the Right Type of Machine

Determine your requirements and choose the machine type accordingly. There is no benefit of investing in an industrial sawdust pellet mill if you have to make pellets in a small quantity or for home use.

Compare Prices

Use the internet to your advantage. Create a list of reputable pellet mill manufacturers and request them to send you price quotes for the machine type you need.

Once you have quotations from different manufacturers, you can better compare the prices and choose the one you find profitable.

If you negotiate, most companies will offer you a low price for bulk orders. People who have biomass pellet production lines must buy pellet mills in bulk. After all, it is an ideal way to purchase affordable pellet mills.

Consider Chinese Manufacturer

On average, Chinese manufacturers are less expensive than European producers. After all, they have better access to the raw material used for making pellet machines.

Moreover, the competitive shipping industry and cheap labor costs make Chinese pellet mills more budget-friendly.

Choose a Chinese pellet mill manufacturer having at least ten years of experience and a modern production workshop. Besides this, do not forget to check their ISO 9001 2000 certification.

The certification ensures that the company executes and maintains an excellent management system.

Ensure there is no broker between you and the manufacturer. Otherwise, you’ll have to pay an additional cost for the mediator.

Note: Do not run after cheap pellet mills only. Some companies offer low-cost pellet mills, but they use low-quality bearings and other mechanical and electrical components.

With such machines, you will often have to pay for their upkeep and repair. Beware if you notice a company is selling pellet mills at a highly low price.

How Should a Newbie Use a Pellet Mill?

Though pellet mills are user-friendly, you must get some prior training before using them for the first time. Buyers who purchase machines from resellers or retailers struggle to get support sometimes.

Therefore, you should buy them from the manufacturer directly. Below are the steps to use a new pellet mill.

Read User Manuals and Guide

Read all the user manuals provided by your manufacturer. You must have received drawings, manuals, and videos for the proper operation.

Assembling of the Parts

If your machine is not pre-assembled, assemble it following the instructions of your manufacturer. Make sure the feeder, discharge hole, and motor are perfectly installed. Tight any loose nut and bolt you find.

Installation of the Machine

Choose a firm surface to install the machine. Fix it into a concrete base so that it does not shake when running.

Add Lubricating Oil

Before you start the pellet mill, add lubricating oil to the gearbox, shaft, and roller. Before you start your machine, make sure all of the moving parts are lubricated. Lubricate roller after every four hours, while the main shaft after every 8 hours.

Also, lubricate your gearbox after every six months.

The modern pellet mill comes with an automatic lubricating system so you can work longer without stopping it.

Check the Roller and Die

Make sure the die and roller are clean. They should be free of debris. Ensure nothing is obstructing them. Also, check for any friction and abrasion in the roller and die.

Preheat Your Pellet Mill Before Using it

You must preheat the machine before using it. If you will start making pellets as soon as the machine starts, you may notice some cracks on it. Let the temperature of the machine touch 50 degrees celsius.

Analyze the Rotating Direction

Ensure the die and roller and rotating in the right direction.

Check the Safety

An operator must check for possible power leakage in the electric cabinet, motor, and wires.

How to Maintain a Pellet Mill?

The regular maintenance of a pellet mill can increase its life span and efficiency several times. You can follow the below step for the maintenance of your pellet-making machine.

Inspection of the Machine

Inspect your overall pellet mill and crucial parts like roller, die, bearings, and gears regularly. It can prevent massive failures and accidents.

Replace the wearing parts right away if you notice they need replacement.

Make sure the operator is not overloading the machine as it can damage and reduce the performance of the motor and gear in the long run.

Cleaning of the Machine

Your pellet-making mill must be clean every time you use it. Some operators neglect it, but it enhances the efficiency of the machine to a great extent. Clean the die and rollers on a regular basis.

Eliminate the dust and other unwanted objects from the machine before using it. Clean the die with gasoline.

Wash the roller every time you use it. It will ensure that it is clean for the next use.

Lubrication of The Machine

Lubrication helps, but only when you use suitable lubricants. Use a lithium-based lubricant two times a day to lubricate the die and rollers. For the lubrication of gears, you can use hyperbolic gear oil.

Follow Your Manufacturer’s Guidelines for Operation

Make sure you are following guidelines from your manufacturer for operation. Do not put in other than recommended raw material for making pellets.

If you are operating a wood pellet machine, do not add anything else than wood powder, crush, and other appropriate material.

Since the die of pellet making machine blocks frequently, you should clean it with oil soaking. Otherwise, the shape of your pellets will not be accurate.

In addition to this, do not forget to preheat the machine before using it.

How to Make a Pellet Mill Machine?

An industrial pellet mill is a high-tech machine, made after integrating a lot of research and development. Only a well-equipped and experienced manufacturer can make a quality pellet mill.

Below are a few steps to manufacture a pellet mill.

Designing of the Exterior

A team of designers works together to design the exterior of a pellet machine. They aim to make the machine compact, efficient, and user-friendly.

The feeding conveyor, power distributing cabinet, and dust collector are designed to keep user-friendliness in mind.

Make sure the manufacturer you choose uses high-quality, 100% galvanized metal for the interior and exterior. The company should also use premium quality paint that protects the machine against rust.

Crucial Interior Parts of the Mill

A pellet mill comprises several parts. However, a few major ones include dies, rollers, bearings, and pellet cutting knives.

Let us understand the functioning of these parts.

Die

Die is the primary part of the mill that processes the raw material into pellets. Generally, you will find one out of the following two types of the die.

Ring Die

It has a cylindrical shape with several holes through which raw materials are pushed into pellets. Manufacturers use a gun drill and vacuum furnace to make the die.

Flat Die

Flat die, on the other hand, has two or three rollers. And the material drops down into the chamber by its weight.

Rollers

Rollers let you blend the material and put it into the hole of the die. The ring die has only two rollers, while the flat die has three.

Bearings

Bearings are another prime part of the pellet mill that ensures stable functioning. They reduce mechanical friction and make sure that the equipment runs smoothly and efficiently.

Shell of Roller

It is the location where raw materials are squeezed using a die. Make sure your potential manufacturer uses a good quality alloy steel for making these rollers.

Pellet-Cutting Knives

As the name suggests, knives cut pellets and provide the required size. These are stainless steel knives that cut pellets accurately every time.

Tcpel pellet mill has a compact design. It comes with a unique motor and industrial speed reducer for convenient operation. All the crucial parts like shaft and rollers have been assembled in a dust-free workshop.

Tips When Buying a Pellet Mill

In order to serve you better, please try to provide the below information:

1) What is the material to make wood pellets? Better if you can share us some pictures

2) Hardness of your material?

3) Moisture content?

4) Maximum diameter of the material to be processed?

5)The capacity per hour you want to get for the pellet production.

Then we will recommend suitable model based on your actual needs.