How to Make Ice Melt Pellets With Our Pellet Machine?

Case Study: Ice Melt Pellets Production for Korean Government Project

In winter, many regions experience heavy snowfall or even blizzards, which significantly affects transportation and daily mobility. As a result, the demand for snow melting pellets rises dramatically. Recently, we received a request from a Korean client who needed a reliable solution for melting snow around the Blue House (Cheong Wa Dae), the executive office and official residence of the South Korean President.

To address this, we utilized our pellet machine to produce high-quality driveway ice melt pellets, offering the client a tailor-made and effective solution.

The client had strict requirements for the snow melting pellets:

* They should not melt the snow too quickly or too slowly.

* They must be easy to store.

* The pellets should have high hardness and durability.

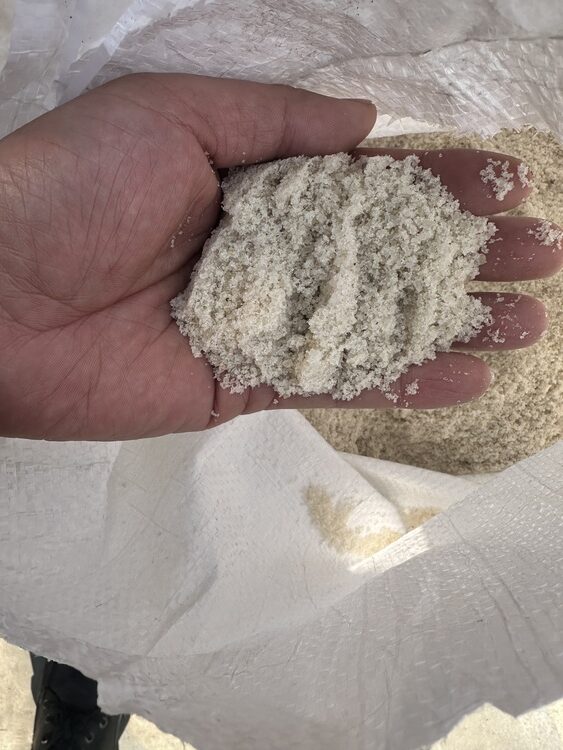

As this was a municipal-level project, the client brought their raw materials directly to our factory for testing. The materials provided were sea salt and magnesium flakes, blended in a 3:2 ratio. The required output was approximately 2 tons per hour.

We recommended our 55kW pellet machine model TCF550, which delivered excellent performance during testing.

Production Process:

First, the sea salt and magnesium flakes were thoroughly mixed. We pre-conditioned the pellet machine by grinding a mixture of oily materials and wood sawdust to polish the die, ensuring smooth pellet formation. Once the machine was ready, the blended raw materials were fed into the pelletizer.

The final ice melt pellets had a diameter of 4mm, with a length ranging between 2 to 5 cm.

Whole Working and Testing Process Video

Advantages of De-Icing Pellets Over Traditional Rock Salt:

1. Faster and More Effective Melting at Low Temperatures

Traditional rock salt (NaCl) loses effectiveness below -9°C.

Magnesium chloride pellets remains effective at temperatures as low as -20°C, making it ideal for extreme cold climates.

2. Better Storage and Handling

Regular salt easily absorbs moisture and clumps, making it hard to store and apply.

Compressed magnesium chloride ice melt pellets are dry, hard, and resistant to moisture, ensuring long shelf life and convenient distribution.

3. Reduced Corrosion

Rock salt is highly corrosive to concrete, metal, and vehicle underbodies.

Magnesium chloride pellets is much less corrosive, especially in pellet form, as it dissolves more slowly.

4. Safer for Plants and Pets

Sodium chloride is harmful to plant roots and can damage lawns and green areas. It also irritates pets’ paws.

Magnesium chloride ice melt pellet is significantly more eco-friendly and pet-safe, with many products labeled accordingly, so it’s also called “Eco-friendly ice melt” or “Pet safe de-icer”

Client Feedback & Future Cooperation

The client was extremely satisfied with the performance of our pellet machine. Since they need to prepare driveway ice melt pellets in advance each winter, they have indicated plans for additional future purchases.

If you also need to produce ice melt pellets in advance, our pellet machine can fully meet your production needs. In addition to ice melt pellets, our pellet machines are also capable of producing inorganic fertilizer pellets, animal feed pellets, and biomass fuel pellets.

Talk to An Expert

SHARE THIS POST

Talk to An Expert